PV/Photovoltaic Module/Panel End Welding for PV Module String Introduction:

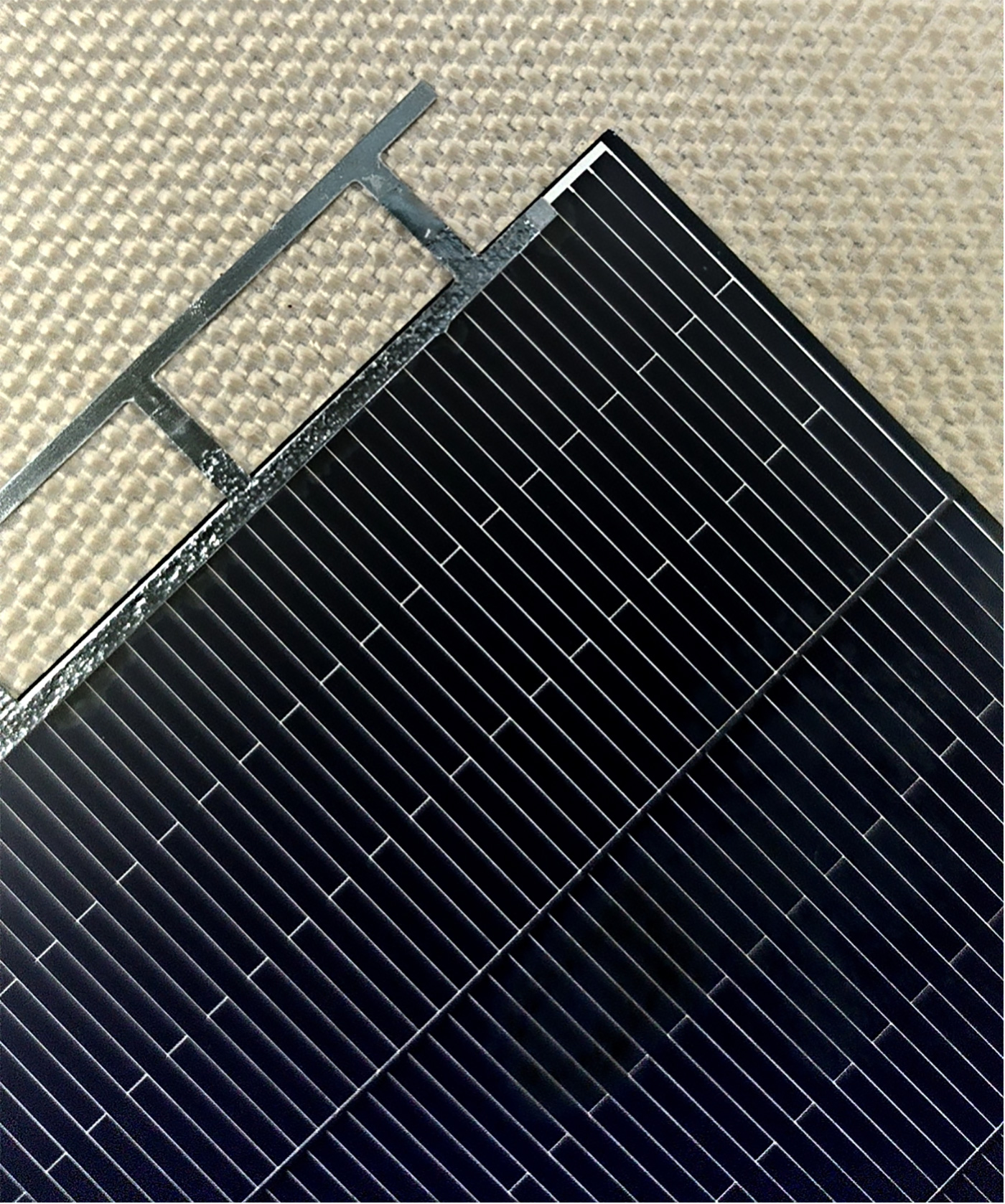

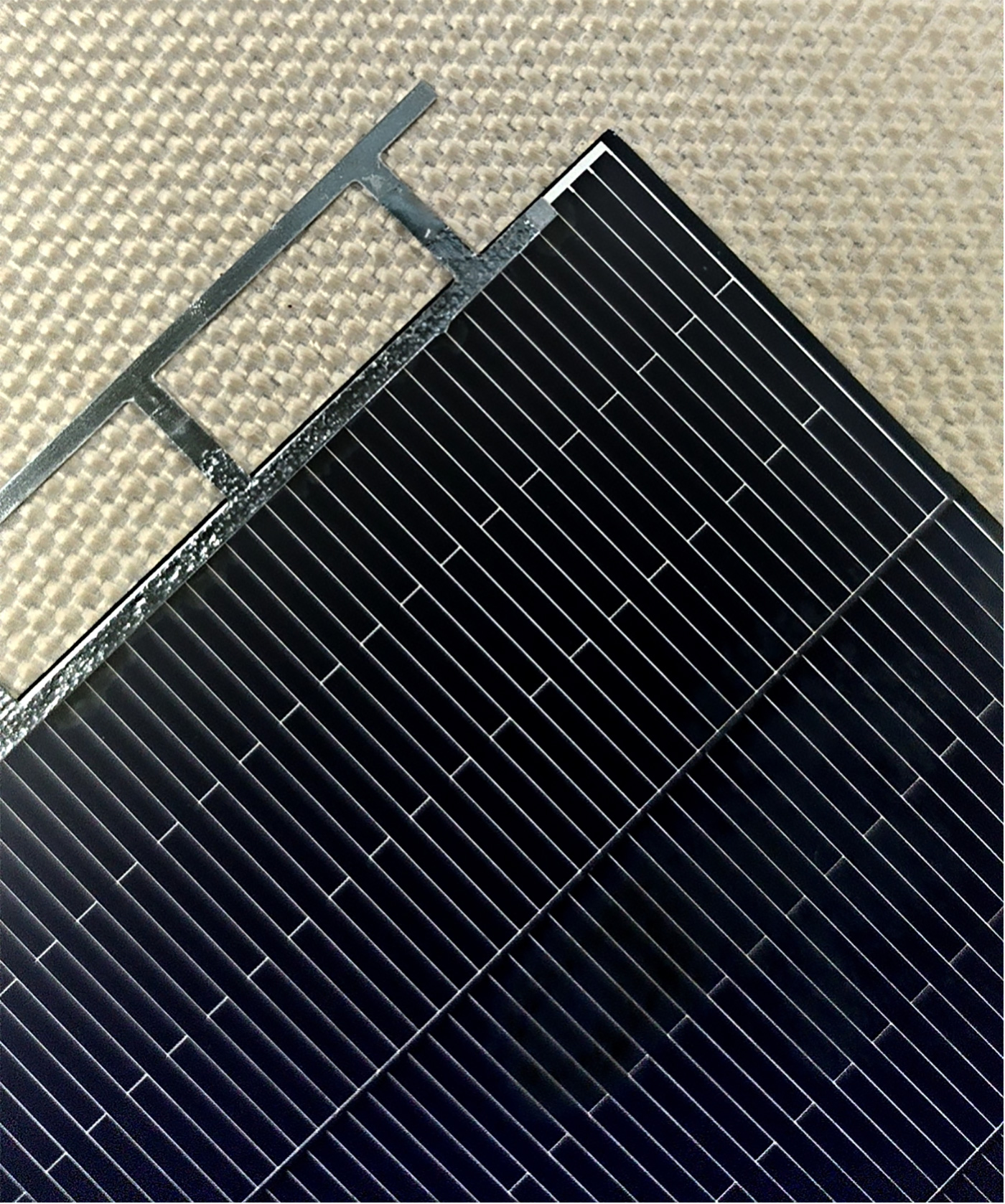

1.Photovoltaic Module End Welding for PV Module String can make 156 / 178 / 182 / 210 cells with super compatibility, and can realize the welding of the bus bar at both ends of the half-cell module, the conventional whole module and the double glass module

2.Modular production of bus bar, 5-20kg feeding by shaft, L-shaped, U-shaped and straight bar cutting at both ends

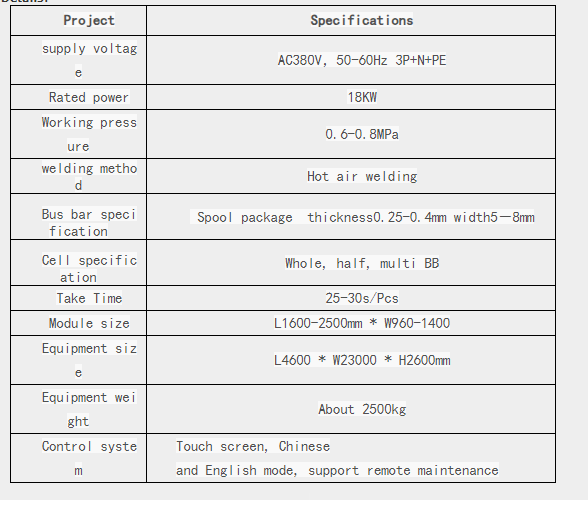

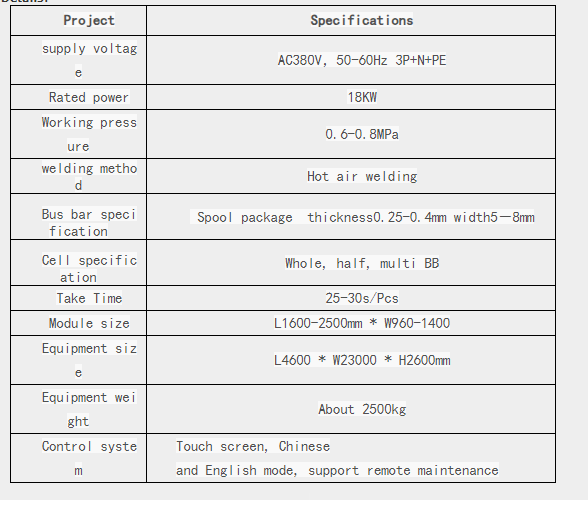

3.Vacuum adsorption of cell string and suspended welding of bus bar Details: Project Specifications supply voltage AC380V,50-60Hz 3P+N+PE Rated power 18KW Working pressure 0.6-0.8MPa welding method Hot air welding Bus bar specification Spool package thickness0.25-0.4mm width5-8mm Cell specification Whole, half, multi BB Take Time 25-30s/Pcs Module size L1600-2500mm * W960-1400 Equipment size L4600 * W23000 * H2600mm Equipment weight About 2500kg Control system Touch screen, Chinese and English mode, support remote maintenance