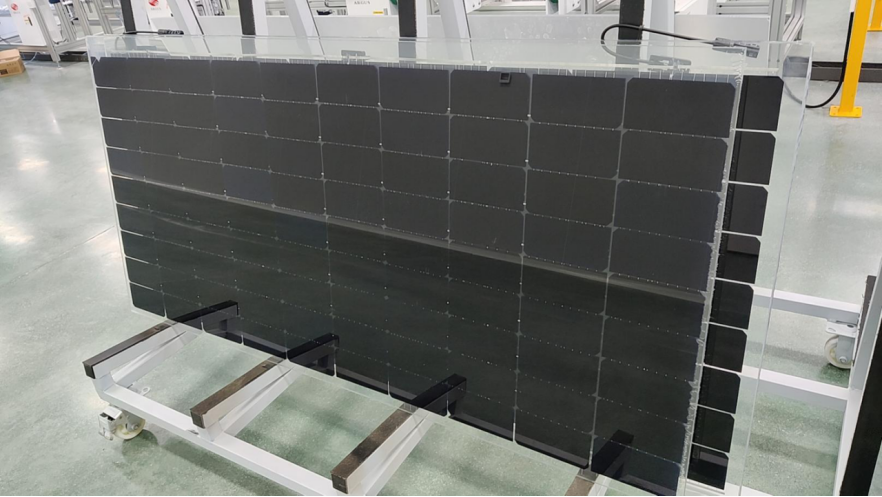

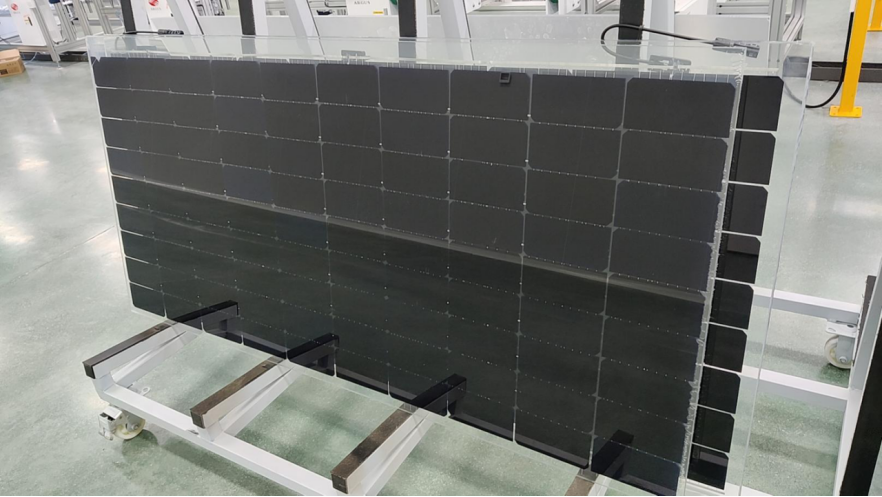

1. Welding control: PLC is used to control the welder

2. Welding method: electromagnetic induction hot melt method

3. After welding, the busbar is firm, without burrs, tin accumulation, cold solder joints, desoldering and other abnormal conditions;

4. The busbar passes through the electromagnetic heating device, first positioning and pressing the busbar and the welding belt, and then heating and melting the tin layer on the surface of the welding belt through the magnetic field. After the two are combined, they are solidified by cooling air

5. After the busbar is welded, a clear welding texture can be formed, which is convenient for subsequent visual inspection

The equipment uses a mobile module with a servo motor precision screw and a linear guide guide, which has the advantages of fast, sensitive, and accurate in place;

Equipment Parameter

Item | Performance Index | Item | Performance Index |

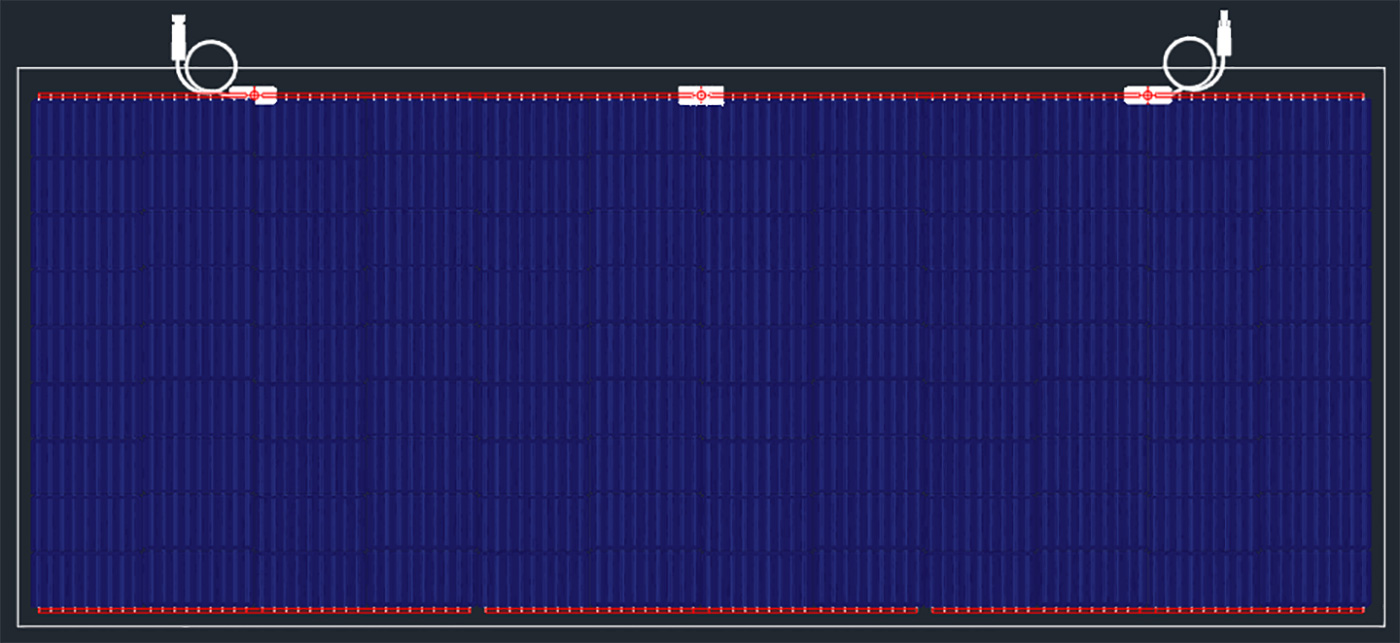

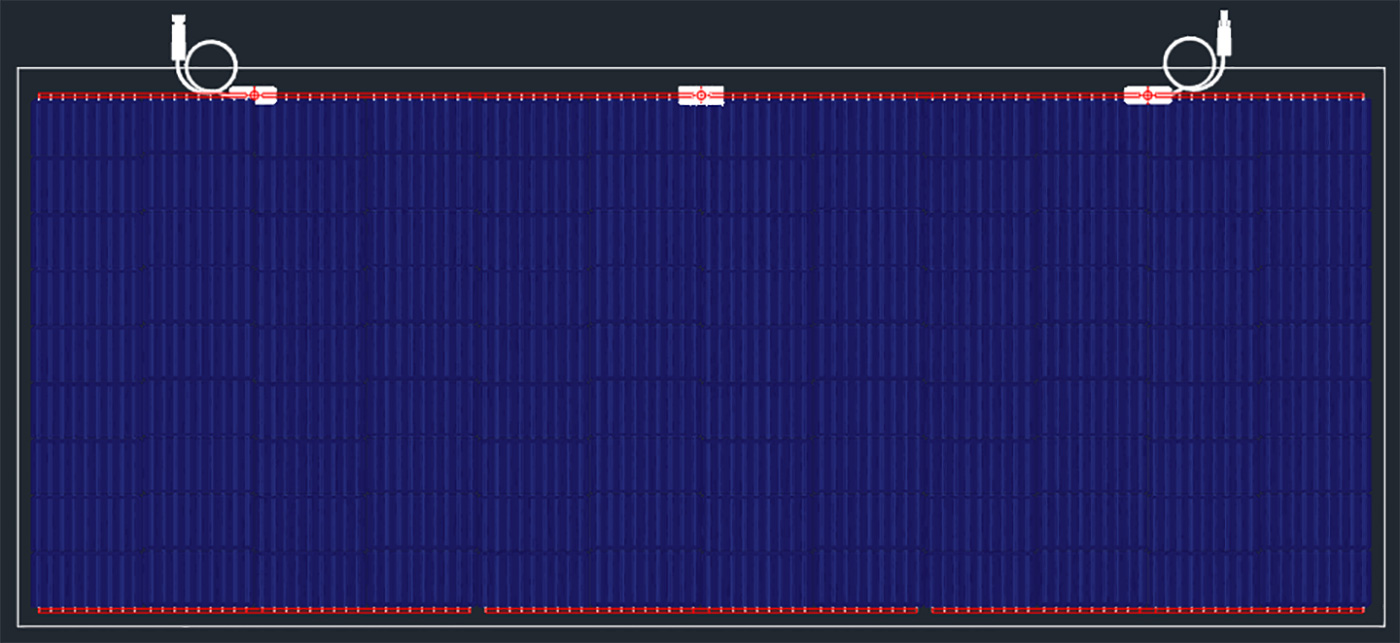

Scope Of Application | Pattern Drawing | Overall Dimension | 4000*1800*2500mm |

Equipment Weight | 2500KG | Air Source | 0.6-0.8mpa Φ16mm Trachea 1000/Lmin |

Power Supply Requirement | 3ψ5W,380V,50/60Hz | Feed Direction | Long Side Forward |

Equipment Power | 20KW | Transfer Speed | 20m/min |

Welding Mode | Electromagnetic Type | Operating Interface | 10 Inch Touch Screen |

Use Environment | 25±5℃ | Humidness | ≤80% (No Condensation) |

Device Password Protection | Multi-Level Operation Password Protection | Working Beat | According To The Model 30S/ Block |

Fragmentation Rate | 0.05‰(APorn) | Glass Feeding Normalization | <1mm |